Specular Metrology

High accuracy 3D analysis and measurement of shiny surfaces

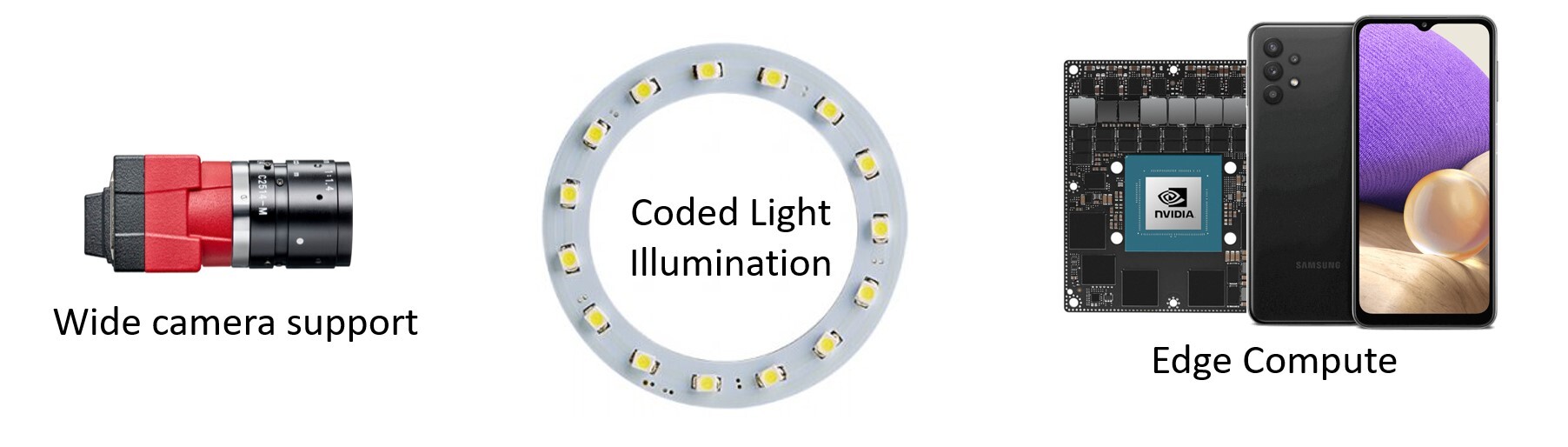

Umajin provides a flexible framework of hardware choices and unique patented 3D processing allows machine vision to be applied with highly accurate photometric measurements. Specular photometry provides the opportunity to significantly improve quality and accurately understand the condition of key components.

Imaging and inspecting highly reflective surfaces has been very challenging. Specular photometry is the answer, providing highly detailed 3D images. These images can be analysed using A.I machine vision to fully automate the process of inspection, radically improving quality and maintenance processes.

Two distinct use cases for this technology are;